AR’s Impact on Supply Chain: 12% Accuracy by 2026

Augmented reality is set to revolutionize supply chain logistics, driving a projected 12% increase in accuracy by December 2026 through improved operational efficiency and real-time data integration.

Imagine a future where logistics errors are minimized, efficiency is maximized, and every package arrives precisely as intended. This isn’t a distant dream; it’s the tangible promise of augmented reality. The critical impact of AR on supply chain logistics: achieving 12% greater accuracy by December 2026 is no longer a speculative forecast but a strategic imperative for businesses aiming to stay competitive in an increasingly complex global market.

The AR Revolution in Warehouse Operations

Augmented reality (AR) is fundamentally changing how warehouses operate, transforming traditional, often manual, processes into highly efficient, data-driven workflows. By overlaying digital information onto the physical world, AR empowers workers with real-time insights and guidance, significantly reducing the potential for human error and accelerating task completion.

This integration is not just about speed; it’s about precision. Workers can receive visual instructions for picking, packing, and sorting, ensuring that the right items are handled correctly every time. The result is a substantial uplift in operational accuracy, directly contributing to the ambitious target of a 12% improvement across the supply chain by 2026.

Enhanced Picking Efficiency with AR Glasses

One of the most immediate and impactful applications of AR in warehouses is in order picking. Traditional pick-and-pack methods often rely on paper lists or handheld scanners, which can be slow and prone to error. AR glasses, however, provide a hands-free, visual guidance system.

- Visual Navigation: Workers see digital arrows and directions overlaid on the warehouse floor, guiding them to the exact location of items.

- Real-time Information: Product details, quantity, and specific storage instructions appear directly in their field of vision.

- Error Reduction: Confirms the correct item has been picked through visual cues, minimizing mispicks and returns.

These capabilities translate into faster picking rates and, more importantly, a drastic reduction in picking errors. The efficiency gains are measurable, directly contributing to the overall accuracy goals of modern logistics networks.

Streamlining Inventory Management

Beyond picking, AR plays a crucial role in modernizing inventory management. Keeping track of thousands of SKUs across vast warehouse spaces is a monumental task. AR simplifies this by providing instant access to inventory data overlayed on physical shelves.

Workers can quickly scan shelves with AR devices to identify stock levels, locate specific products, and even conduct rapid cycle counts. This real-time visibility eliminates the need for manual data entry and reduces discrepancies between physical and digital inventory records. The ability to verify stock on the spot ensures that inventory data is always current and accurate, which is vital for efficient supply chain planning and execution.

The integration of AR in warehouse operations represents a paradigm shift. It moves beyond incremental improvements, offering a transformative leap in efficiency and precision. As more companies adopt these technologies, the collective impact on supply chain accuracy will be profound, laying the groundwork for achieving and even surpassing the 12% accuracy target.

Predictive Maintenance and Quality Control with AR

Augmented reality extends its reach beyond immediate operational tasks, offering significant advantages in predictive maintenance and quality control within the supply chain. By providing technicians and quality inspectors with powerful visual tools, AR minimizes downtime, ensures product integrity, and further contributes to the overall accuracy and reliability of logistics processes.

The ability to instantly access critical data and receive remote expert assistance through AR devices revolutionizes how maintenance and quality checks are performed. This proactive approach prevents issues before they escalate, safeguarding against costly disruptions and maintaining high standards throughout the supply chain.

AR-Guided Inspections and Troubleshooting

For quality control, AR enables inspectors to conduct thorough and consistent checks. Digital checklists and visual guides can be overlaid on products or machinery, ensuring every step of an inspection is followed accurately. This reduces subjectivity and human error, leading to more reliable quality assessments.

- Standardized Procedures: AR ensures that inspection protocols are consistently applied by all personnel.

- Defect Identification: Visual overlays can highlight common defect areas or provide examples of acceptable standards.

- Data Capture: Inspectors can document findings, take photos, and log data directly through their AR devices, streamlining reporting.

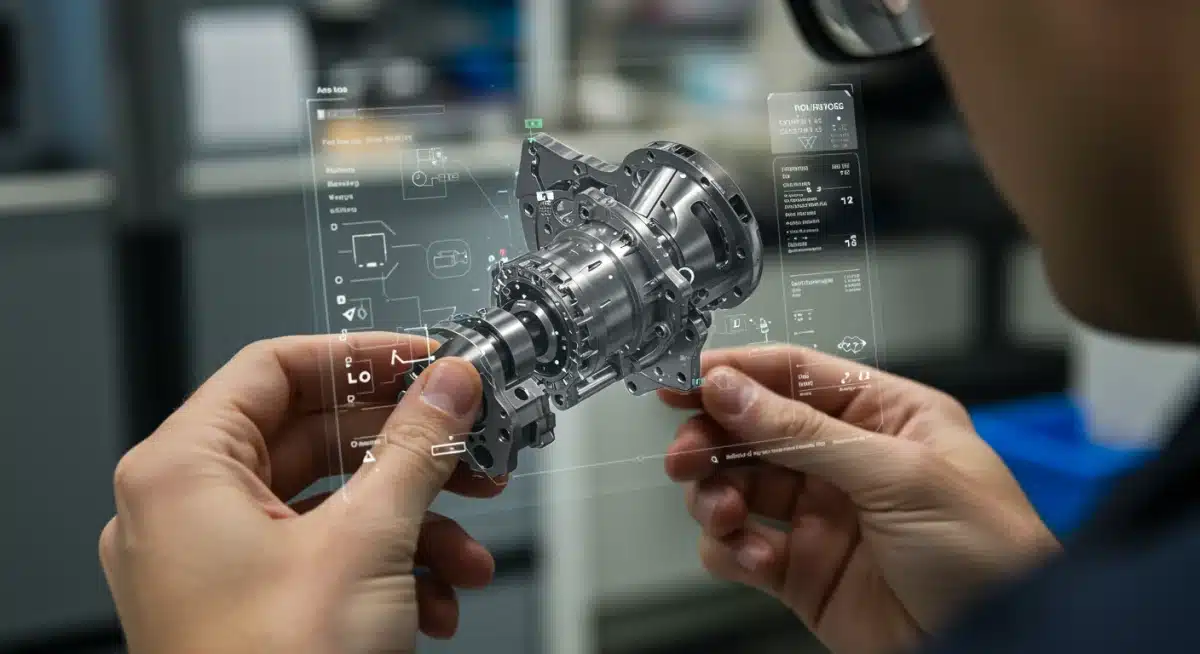

In the realm of predictive maintenance, AR empowers technicians to diagnose and repair complex machinery with unprecedented efficiency. Instead of relying solely on manuals or memory, they can see digital schematics, performance data, and repair instructions projected onto the equipment itself.

Remote Expert Assistance and Training

One of AR’s most powerful features in this context is its capacity for remote assistance. When a technician encounters an unfamiliar problem, a remote expert can see exactly what the technician sees through their AR glasses. The expert can then annotate the technician’s field of view, drawing circles, arrows, or even overlaying 3D models to guide them through the repair process step-by-step.

This capability dramatically reduces the need for experts to travel to remote locations, saving time and resources. Furthermore, AR-powered training simulations allow new employees to practice complex procedures in a safe, guided environment, accelerating their skill development and ensuring they are proficient before handling real-world equipment. The combination of enhanced quality control and efficient predictive maintenance through AR is instrumental in boosting the overall accuracy targets for supply chain operations.

Optimizing Last-Mile Delivery with AR Navigation

The last mile of delivery is often the most challenging and costly segment of the supply chain. It’s where goods transition from distribution hubs to their final destinations, encountering complex urban environments, varied customer requirements, and tight schedules. Augmented reality is emerging as a game-changer in this critical phase, offering solutions that enhance navigation, improve delivery accuracy, and optimize routing.

By providing drivers with real-time, context-aware information, AR helps overcome common last-mile hurdles, ensuring timely and precise deliveries. This directly contributes to the overarching goal of achieving greater accuracy across the entire supply chain, extending the benefits of AR from the warehouse floor to the customer’s doorstep.

Enhanced Driver Guidance and Route Optimization

AR navigation systems go beyond traditional GPS. Instead of a flat map, drivers see digital overlays on their windshields or through head-mounted displays, indicating the optimal route, identifying specific buildings, and even highlighting package drop-off points. This visual guidance is intuitive and reduces cognitive load, allowing drivers to focus on the road while still receiving crucial delivery information.

- Dynamic Route Adjustments: AR systems can integrate real-time traffic data to suggest alternative routes, avoiding delays.

- Precision Location: Overlays can pinpoint exact building entrances or loading docks, preventing misdeliveries.

- Package Identification: Drivers can confirm they have the correct package for a specific stop with visual cues.

This level of precision in navigation and information delivery minimizes wrong turns, reduces delivery times, and most importantly, significantly decreases instances of incorrect deliveries. The accuracy gains here are substantial, directly impacting customer satisfaction and operational efficiency.

Proof of Delivery and Customer Interaction

AR can also enhance the proof-of-delivery process. Drivers can use AR-enabled devices to capture visual evidence of delivery, such as a package at a doorstep, with geo-location and timestamp data automatically embedded. This provides irrefutable proof and helps resolve disputes quickly.

Furthermore, AR can improve customer interaction. For example, if a customer needs to sign for a package, the AR device could project the signature field directly onto a digital pad, streamlining the process. The ability to verify delivery with high precision and integrate seamlessly with customer-facing aspects reinforces the accuracy improvements driven by AR throughout the final leg of the supply chain journey. These advancements are crucial for meeting the 12% accuracy target by 2026.

AR’s Role in Training and Workforce Empowerment

The successful integration of augmented reality into supply chain logistics hinges not only on the technology itself but also on the workforce’s ability to effectively utilize it. AR plays a transformative role in training new employees and upskilling existing staff, empowering them with the knowledge and confidence to operate complex systems and execute tasks with superior accuracy. This focus on human capability, augmented by technology, is a cornerstone of achieving the projected 12% increase in accuracy by December 2026.

By providing immersive, hands-on learning experiences, AR reduces training time, enhances retention, and ensures a highly competent workforce capable of navigating the demands of a modern supply chain.

Immersive Training Simulations

Traditional training methods often involve lengthy manuals, classroom sessions, or shadowing experienced colleagues. While valuable, these methods can be slow and less engaging. AR training simulations, however, offer an interactive and practical approach.

- Virtual Overlays: New hires can practice tasks like order picking or equipment operation with digital guides overlaid on real-world objects.

- Step-by-Step Instructions: Complex procedures are broken down into manageable steps, with visual cues for correct execution.

- Safe Learning Environment: Trainees can make mistakes in a virtual setting without real-world consequences, fostering confidence.

This direct, experiential learning accelerates the onboarding process, allowing new employees to become productive much faster. More importantly, it instills a deeper understanding of tasks, leading to fewer errors once they are on the job, thereby directly impacting operational accuracy.

Upskilling and Continuous Learning

For existing employees, AR offers continuous learning opportunities. As new equipment is introduced or processes are updated, AR modules can quickly train staff on the changes. This ensures that the workforce remains agile and adaptable to evolving supply chain demands.

Furthermore, AR can facilitate on-the-job guidance. If a worker encounters an unfamiliar situation or needs a refresher on a specific procedure, they can access AR-powered instructions in real-time. This reduces reliance on supervisors for every query and empowers workers to troubleshoot independently, enhancing overall efficiency and accuracy. The investment in AR for workforce empowerment is an investment in human capital, directly correlating with improved operational precision and the realization of ambitious accuracy targets.

Data Integration and Real-time Analytics through AR

The true power of augmented reality in supply chain logistics goes beyond mere visual overlays; it lies in its ability to seamlessly integrate with existing data systems and provide real-time analytics. This data-driven approach is critical for achieving the ambitious target of a 12% increase in accuracy by December 2026. By connecting the physical and digital worlds, AR transforms raw data into actionable insights, enabling faster, more informed decision-making across the entire supply chain.

This integration allows for a continuous feedback loop, where data collected through AR devices can be analyzed instantly, leading to immediate process improvements and a more responsive logistics network.

Connecting Physical Actions to Digital Data

AR devices act as intelligent interfaces that capture information from the physical environment and feed it directly into digital systems. For instance, when a warehouse worker scans a barcode with an AR headset, not only does the item’s information appear in their field of vision, but that scan also updates the central inventory management system in real-time. This eliminates delays and manual errors associated with traditional data entry.

- Automated Data Capture: Actions performed via AR are automatically logged, ensuring data consistency.

- Reduced Latency: Information flows instantly between the physical operation and the digital system.

- Enhanced Visibility: Managers gain immediate insights into operational progress and potential bottlenecks.

This direct link between physical action and digital record-keeping is fundamental. It ensures that all stakeholders, from warehouse managers to supply chain planners, are working with the most current and accurate information available. The reduction in data discrepancies is a significant contributor to the overall accuracy improvements.

Actionable Insights from Real-time Analytics

With AR-powered data integration, supply chain analytics move from retrospective reporting to real-time insight generation. Managers can monitor key performance indicators (KPIs) as they happen, identifying inefficiencies or emerging problems instantly. For example, if picking rates in a certain zone drop below a threshold, AR data can immediately flag it, allowing for quick intervention.

Furthermore, AR can present these analytics in an easily digestible format, projected onto dashboards or even directly into a supervisor’s AR glasses. This enables proactive management, allowing for adjustments to be made on the fly, optimizing resource allocation, and preventing minor issues from escalating into major disruptions. The ability to act on real-time, accurate data is paramount for continuous improvement and achieving the ambitious accuracy goals set for the modern supply chain.

Challenges and Future Outlook for AR in Logistics

While the potential of augmented reality in supply chain logistics is immense, and the goal of achieving 12% greater accuracy by December 2026 is within reach, its widespread adoption is not without challenges. Addressing these hurdles will be crucial for realizing the full transformative power of AR. However, the future outlook remains overwhelmingly positive, with continuous advancements in technology and increasing industry recognition of AR’s value.

Overcoming current limitations will pave the way for AR to become an indispensable tool, further embedding itself into the fabric of efficient and accurate supply chain operations.

Overcoming Adoption Hurdles

Several factors currently influence the pace of AR adoption in logistics. One significant challenge is the initial investment cost associated with AR hardware (headsets, smart glasses) and software development. For smaller businesses, this can be a barrier to entry. Another hurdle is workforce acceptance and training. While AR training itself is effective, integrating new technology into daily routines requires a cultural shift and dedicated support.

- Cost-Benefit Analysis: Businesses need clear demonstrations of ROI to justify initial investments.

- User Experience: Devices must be comfortable, intuitive, and seamlessly integrate into existing workflows.

- Data Security: Robust protocols are needed to protect sensitive supply chain data accessed via AR.

Addressing these challenges involves developing more affordable and user-friendly AR solutions, coupled with comprehensive training programs that highlight the benefits for individual workers, not just the organization.

The Evolving Landscape of AR Technology

The rapid evolution of AR technology promises to mitigate many of these current challenges. Hardware is becoming lighter, more powerful, and less expensive. Software platforms are becoming more sophisticated, offering easier integration with existing enterprise systems. The development of AI-powered AR will further enhance capabilities, allowing for more intelligent assistance and predictive insights.

Looking ahead, we can anticipate more seamless integration of AR with other emerging technologies like the Internet of Things (IoT) and 5G networks. This will create hyper-connected supply chains where every asset, process, and worker is intelligently linked, leading to unprecedented levels of visibility and accuracy. The journey towards a 12% accuracy increase is just the beginning, with AR poised to drive even greater efficiencies and resilience in the years to come.

| Key Aspect | Impact on Accuracy |

|---|---|

| Warehouse Operations | Reduces picking errors, streamlines inventory management with visual guidance. |

| Maintenance & Quality | Enables precise inspections and remote expert troubleshooting, minimizing downtime. |

| Last-Mile Delivery | Optimizes routes and ensures precise package drop-offs, reducing misdeliveries. |

| Workforce Training | Accelerates skill acquisition and reduces human errors through immersive simulations. |

Frequently Asked Questions About AR in Supply Chain

The primary goal is to achieve a 12% greater accuracy in supply chain operations by December 2026. This is driven by AR’s ability to enhance efficiency, reduce human error, and provide real-time data insights across various logistics processes, from warehousing to last-mile delivery.

AR glasses provide visual guidance to pickers, overlaying digital arrows and product information directly into their field of vision. This hands-free system ensures workers go to the correct location and pick the right items, significantly reducing mispicks and accelerating the picking process.

Absolutely. AR enables technicians to perform predictive maintenance with digital schematics and offers remote expert assistance. For quality control, it provides visual checklists and standardized procedures, ensuring consistent and accurate inspections, thus minimizing operational disruptions.

AR optimizes last-mile delivery by offering advanced navigation with real-time overlays, guiding drivers to precise drop-off points. It also streamlines proof-of-delivery by enabling visual documentation, reducing delivery errors, and improving overall customer satisfaction.

Yes, challenges include initial investment costs for hardware and software, and ensuring workforce acceptance and proper training. However, ongoing technological advancements are making AR solutions more affordable, user-friendly, and easier to integrate, addressing these hurdles effectively.

Conclusion

The journey towards a 12% greater accuracy in supply chain logistics by December 2026, driven by augmented reality, is not merely an aspiration but a strategic direction for forward-thinking businesses. From revolutionizing warehouse operations and streamlining inventory management to empowering workforces through immersive training and optimizing last-mile deliveries, AR is proving to be an indispensable tool. While challenges in adoption and integration exist, the continuous evolution of AR technology, coupled with its proven benefits in reducing errors and enhancing efficiency, positions it as a cornerstone of future-proof supply chain strategies. Embracing AR today means investing in a more precise, resilient, and competitive logistics network for tomorrow.