AR for Product Design in 2026: Accelerating US Manufacturing Cycles

Augmented Reality (AR) is poised to significantly accelerate product design cycles for US manufacturers by 18% by 2026, enabling faster prototyping, improved collaboration, and reduced errors, thus driving competitive advantage and market responsiveness.

The landscape of product development is undergoing a profound transformation, with emerging technologies reshaping how US manufacturers innovate. By 2026, AR for product design in 2026: accelerating development cycles by 18% for US manufacturers is not merely a预测; it’s a strategic imperative, promising unprecedented efficiencies and a significant competitive edge. This shift is driven by the urgent need for faster time-to-market and enhanced design precision in an increasingly dynamic global economy.

The Dawn of AR in Product Development

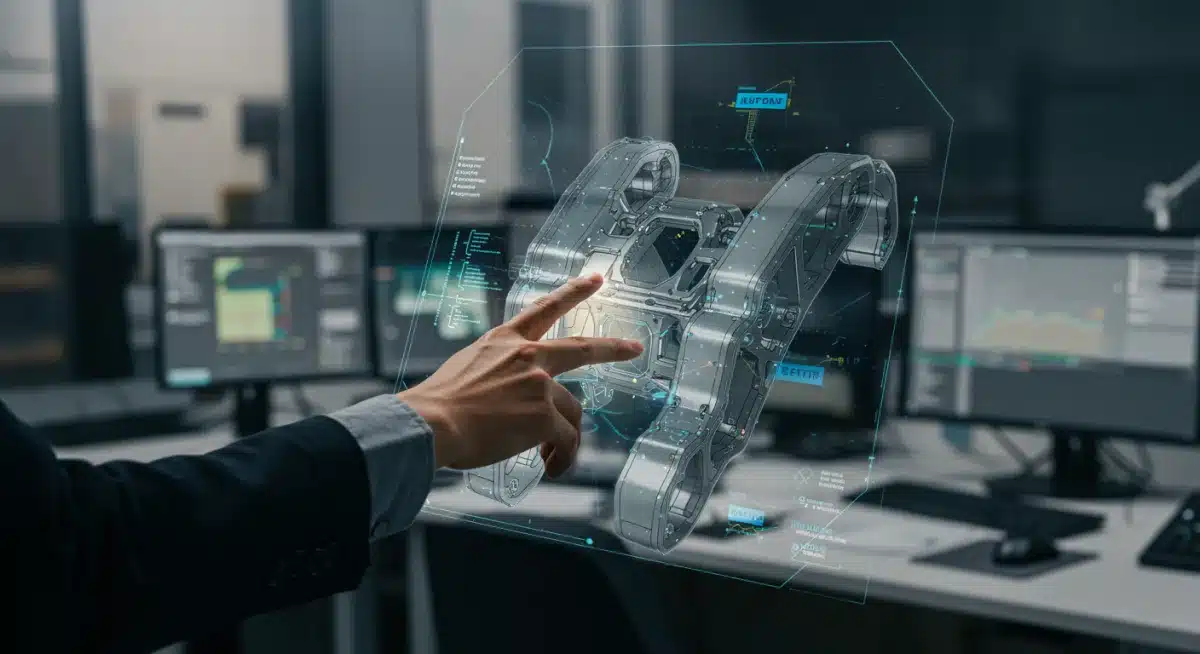

Augmented Reality (AR) is no longer a futuristic concept confined to science fiction; it is a tangible tool actively being integrated into critical industrial processes. In the realm of product development, AR offers a paradigm shift, moving beyond traditional 2D sketches and static 3D models to immersive, interactive experiences. This technology overlays digital information onto the real world, allowing designers and engineers to visualize and manipulate virtual prototypes within their physical environment.

For US manufacturers, this means a direct and immediate interaction with design iterations. Imagine walking around a virtual full-scale prototype of a new automobile, examining its components, and even simulating its functionality, all within the confines of a design studio or factory floor. This level of immersion fosters a deeper understanding of the product’s form, fit, and function long before any physical materials are committed.

Visualizing Complex Assemblies

One of AR’s most immediate benefits lies in its ability to present complex assemblies in an intuitive manner. Engineers can see how individual parts fit together, identify potential clashes, and refine designs with unparalleled clarity. This visual fidelity drastically reduces ambiguities that often arise from interpreting 2D drawings or even flat-screen 3D models.

- Overlaying digital models onto physical mock-ups.

- Identifying inter-component conflicts in real-time.

- Facilitating ergonomic assessments of virtual products.

- Ensuring precise alignment during assembly planning.

The ability to visualize and interact with these digital twins in a shared AR space also streamlines communication across multidisciplinary teams. Design changes can be demonstrated and approved more rapidly, minimizing misinterpretations and rework. This efficiency gain is a cornerstone of the projected 18% acceleration in development cycles.

In essence, AR transforms product design from a sequential, often siloed process into a concurrent, collaborative endeavor. It empowers teams to make more informed decisions earlier in the design phase, which directly translates to reduced errors and a quicker path to production. The implications for US manufacturing competitiveness are substantial, allowing companies to respond to market demands with agility and precision.

Enhanced Collaboration and Communication

Effective collaboration is the lifeblood of successful product development, especially in complex manufacturing environments. Traditional methods often involve multiple iterations of physical prototypes, extensive travel for design reviews, and lengthy communication chains that can introduce delays and misunderstandings. Augmented Reality fundamentally redefines this dynamic, creating a shared digital workspace that transcends geographical boundaries.

With AR, design teams, engineers, marketing specialists, and even external stakeholders can simultaneously view and interact with a virtual product model, regardless of their physical location. This real-time, shared experience fosters a level of engagement and clarity that traditional video conferencing or document sharing simply cannot match. Imagine a designer in Detroit collaborating seamlessly with an engineer in Silicon Valley, both examining the same holographic engine part, pointing out features, and suggesting modifications as if they were in the same room.

Remote Design Reviews

Remote work and distributed teams have become increasingly common, and AR provides a powerful solution for maintaining design integrity and accelerating decision-making in this new paradigm. Design reviews, traditionally a bottleneck in the development process, become highly efficient and productive.

- Conducting immersive design reviews with global teams.

- Annotating virtual models with feedback in real-time.

- Recording review sessions for future reference and compliance.

- Reducing travel costs and associated time expenditures.

The immediate feedback loop facilitated by AR means that design iterations can be approved or modified on the fly, drastically cutting down the time spent waiting for physical prototypes or sequential feedback. This agility is crucial for US manufacturers aiming to maintain a competitive edge in fast-paced markets.

AR platforms are also evolving to include advanced features such as eye-tracking and gesture controls, making the interaction even more intuitive and natural. This seamless integration of human interaction with digital content ensures that communication barriers are minimized, and collective intelligence is maximized. The result is a more cohesive design process, fewer errors, and a significantly faster journey from concept to market.

Rapid Prototyping and Iteration Cycles

One of the most time-consuming and costly aspects of product development has traditionally been the creation and testing of physical prototypes. Each iteration requires materials, manufacturing time, and often specialized equipment, leading to extended development cycles and increased expenses. Augmented Reality offers a transformative alternative by enabling rapid virtual prototyping, dramatically shrinking iteration cycles.

Virtual Mock-ups and Simulations

Instead of building a physical mock-up, designers can create a highly detailed virtual prototype in AR, which can be scaled, rotated, and examined from every angle. This virtual model can then be subjected to various simulations, testing its functionality, durability, and ergonomic properties without ever touching a physical component.

- Creating full-scale virtual prototypes instantly.

- Testing different material properties in a simulated environment.

- Conducting virtual stress tests and performance analyses.

- Evaluating aesthetic variations without physical production.

Furthermore, AR can integrate directly with Computer-Aided Design (CAD) and Product Lifecycle Management (PLM) systems, allowing for seamless updates and version control. Any change made in the CAD software can be immediately reflected in the AR environment, providing real-time feedback to the design team. This interconnectedness ensures that all stakeholders are working with the most current design, eliminating discrepancies and further streamlining the iteration process.

The ability to rapidly prototype and iterate using AR empowers US manufacturers to bring more innovative and refined products to market faster. It reduces waste, saves costs, and significantly shortens the overall product development timeline, contributing directly to the 18% acceleration target.

Reducing Errors and Rework

Errors in the design phase can have cascading and costly consequences throughout the entire product development lifecycle, from manufacturing delays to expensive recalls. Augmented Reality provides a powerful mechanism for identifying and mitigating these errors much earlier, thereby significantly reducing the need for costly rework and improving overall product quality.

By overlaying digital design specifications onto physical components or environments, AR can highlight discrepancies and potential issues with remarkable precision. This is particularly valuable during the assembly stage, where even minor misalignments can lead to major functional problems.

Real-time Quality Checks

AR headsets can guide assembly line workers, providing step-by-step instructions and overlaying virtual templates onto physical parts. This ensures that each component is placed correctly, and that the assembly process adheres strictly to design specifications. Any deviation can be immediately flagged, allowing for instant correction rather than discovery at a later, more expensive stage.

- Overlaying digital blueprints onto physical workspaces.

- Detecting deviations from design specifications in real-time.

- Providing guided assembly instructions to reduce human error.

- Verifying component placement and orientation with high accuracy.

Moreover, AR can be used for virtual inspections, allowing quality control personnel to compare a manufactured product against its digital twin. This can reveal subtle imperfections or inconsistencies that might be missed by the human eye alone. The level of detail and accuracy offered by AR significantly enhances the thoroughness of quality checks, preventing defective products from reaching the market.

The reduction in errors translates directly into less material waste, fewer manufacturing delays, and a stronger reputation for product reliability. For US manufacturers, this means substantial cost savings and a higher return on investment for their product development efforts. The proactive identification and resolution of issues through AR are central to achieving the accelerated development cycles and improved efficiency.

AR Training and Skill Development

The adoption of new technologies often necessitates significant investment in training and skill development for the workforce. Augmented Reality itself offers a revolutionary approach to training, making it more engaging, effective, and accessible. This is particularly crucial for US manufacturers who need to quickly adapt their teams to new design tools and processes.

Traditional training methods, such as manuals or classroom instruction, can be time-consuming and may not adequately prepare employees for real-world scenarios. AR-powered training simulations provide an immersive and hands-on learning experience, allowing employees to practice complex tasks in a safe, virtual environment before working with actual equipment or products.

Immersive Learning Experiences

Imagine a new engineer learning to operate a sophisticated piece of machinery by interacting with its holographic twin, receiving real-time feedback and guidance. This experiential learning accelerates skill acquisition and boosts confidence, leading to a more competent and efficient workforce.

- Simulating complex machinery operation in a safe environment.

- Providing step-by-step holographic instructions for new tasks.

- Offering immediate performance feedback to trainees.

- Reducing the need for physical prototypes in training scenarios.

AR training can also be customized to individual learning paces and styles, ensuring that every employee receives the most effective instruction. This personalized approach is particularly beneficial in industries where precision and adherence to strict protocols are paramount. Furthermore, AR can facilitate ongoing learning and upskilling, keeping the workforce abreast of the latest technologies and design methodologies.

For US manufacturers, investing in AR-based training means a faster onboarding process for new hires, continuous improvement for existing employees, and a more skilled workforce capable of leveraging advanced design tools. This enhanced human capital directly contributes to the overall acceleration of product development cycles and strengthens the manufacturing sector’s innovative capacity.

Future Outlook: AR Integration by 2026

As we look towards 2026, the integration of Augmented Reality into product design for US manufacturers is not just a trend; it’s a foundational shift. The projected 18% acceleration in development cycles is a conservative estimate, given the rapid advancements in AR hardware, software, and AI integration. The future holds even greater potential for this transformative technology.

By 2026, AR systems will be even more sophisticated, offering higher resolution visuals, more intuitive interaction methods, and seamless integration with a wider array of enterprise systems. We will see AR not just as a visualization tool, but as an integral part of the entire product lifecycle management (PLM) ecosystem, from initial concept to end-of-life planning.

Advancements in AR Hardware and Software

Next-generation AR headsets will be lighter, more comfortable, and offer wider fields of view, making prolonged use more practical for designers and engineers. Software will leverage advanced AI algorithms to assist in design optimization, automatically identifying potential design flaws or suggesting improvements based on historical data and performance metrics.

- More ergonomic and powerful AR head-mounted displays.

- AI-driven design assistance and predictive analytics.

- Enhanced haptic feedback for more realistic virtual interactions.

- Interoperability with diverse CAD, CAM, and PLM platforms.

The widespread adoption of 5G and future 6G networks will also play a crucial role, providing the low-latency, high-bandwidth connectivity required for seamless cloud-based AR collaboration and real-time data processing. This will unlock new possibilities for global design teams to work together with unprecedented efficiency.

Ultimately, AR will empower US manufacturers to not only accelerate their development cycles but also to produce more innovative, high-quality, and customer-centric products. This strategic advantage will be vital for maintaining global competitiveness and driving economic growth within the US manufacturing sector. The journey to an AR-powered design future is well underway, promising a transformative impact by 2026 and beyond.

Overcoming Implementation Challenges

While the benefits of Augmented Reality in product design are clear, the path to full implementation for US manufacturers is not without its challenges. Adopting any new technology requires careful planning, significant investment, and a strategic approach to change management. Addressing these hurdles proactively is essential for realizing the full potential of AR and achieving the desired acceleration in development cycles.

One primary challenge is the initial cost of AR hardware and software, which can be substantial for smaller manufacturers. However, as the technology matures and adoption increases, these costs are expected to decrease, making AR more accessible across the industry. Furthermore, the long-term ROI from reduced errors, faster time-to-market, and improved product quality often outweighs the initial investment.

Data Security and Integration

Another critical aspect is the integration of AR systems with existing enterprise software, such as CAD, PLM, and ERP systems. Ensuring seamless data flow and maintaining data security are paramount. Manufacturers must invest in robust IT infrastructure and cybersecurity measures to protect sensitive design information when leveraging cloud-based AR solutions.

- Addressing initial hardware and software investment costs.

- Ensuring seamless integration with existing IT infrastructure.

- Implementing robust data security protocols for design assets.

- Managing the cultural shift and employee training for AR adoption.

Beyond the technical aspects, there’s also the human element. Employees may require extensive training to become proficient with AR tools, and there can be resistance to adopting new workflows. A comprehensive change management strategy, emphasizing the benefits of AR and providing adequate support, is vital for successful employee adoption.

Despite these challenges, the overwhelming advantages offered by AR in terms of efficiency, collaboration, and innovation make its widespread adoption inevitable for US manufacturers. By proactively addressing these implementation hurdles, companies can position themselves to not only meet but exceed the projected 18% acceleration in product development cycles, securing a leading position in the global market.

| Key Aspect | Impact on Product Design |

|---|---|

| Accelerated Cycles | Enables 18% faster development for US manufacturers by 2026. |

| Enhanced Collaboration | Facilitates real-time, immersive design reviews across distributed teams. |

| Reduced Errors | Identifies design flaws early, minimizing rework and associated costs. |

| Cost Efficiency | Lowers prototyping expenses and optimizes resource allocation. |

Frequently Asked Questions About AR in Product Design

The primary benefit is a significant acceleration of product development cycles, projected to be 18% by 2026. AR enables faster prototyping, real-time visualization, and improved decision-making, leading to quicker market entry for new products and enhanced competitiveness for US manufacturers.

AR creates shared virtual spaces where geographically dispersed teams can simultaneously view and interact with 3D product models. This fosters real-time communication, allows for immediate feedback on design changes, and reduces misunderstandings, streamlining the entire collaborative process.

Yes, AR significantly reduces errors by allowing designers to identify and rectify flaws early in the design phase. By overlaying digital models onto physical environments or components, AR highlights discrepancies, ensures precise alignment, and facilitates virtual quality checks, minimizing costly rework.

Initial investment includes AR hardware (headsets, devices) and software platforms. Integration with existing CAD/PLM systems and employee training are also crucial. While costs can be significant initially, the long-term ROI from efficiency gains and error reduction makes it a worthwhile strategic investment.

By 2026, AR is expected to be deeply integrated into the entire product lifecycle, with more advanced hardware, AI-powered design assistance, and seamless connectivity. It will be a critical tool for US manufacturers to maintain global competitiveness, drive innovation, and respond rapidly to market demands.

Conclusion

The transformative power of Augmented Reality in reshaping product design for US manufacturers by 2026 is undeniable. The projected 18% acceleration in development cycles is not merely an efficiency gain; it represents a fundamental shift in how innovation is fostered, how teams collaborate, and how products are brought to market. From rapid virtual prototyping and enhanced cross-functional communication to significant reductions in design errors and improved training methodologies, AR offers a comprehensive suite of benefits. While implementation challenges exist, the strategic advantages for US manufacturing competitiveness are too substantial to ignore. Embracing AR is not just about adopting a new technology; it’s about securing a future where design is faster, smarter, and more integrated than ever before, positioning US manufacturers at the forefront of global innovation.